We firmly believe in a digital-physical future where online networks connect to physical spaces. Generative design, including algorithmic randomness, end-user parameterization, and verifiable uniqueness, is one such program that we expect to port—with existing manufacturing hardware enabling this.

Original title: Generative Manufacturing: Transmuting Code into PhysicalGoods

Original author: Accelxr, 1kx

Original source: Mirror

Compiled by: Lynn, MarsBit

The future of consumer goods is generative.

Today, on-chain generative algorithms are primarily used in the visual arts sector, where artists write code to create digital and interactive works, animations and prints. However, art may only be the first suitable medium for this new on-chain creative process. We believe that on-chain generative media will proliferate across all other consumer goods and luxury verticals, and that this artistic process will uniquely enable new types of physical production through generative manufacturing.

The appeal of generative collections is obvious: consumers crave unique products that reflect their unique identities while also connecting them to the larger community. With the 1/1/x model, generative algorithms achieve this by creating a single piece with a cohesive aesthetic within a broader collection. These unique creations cater to an individual's specific tastes, allowing for fine-grained expression within the tribe, and the rapid popularity of the PFP market and the niche communities that have sprouted around specific generative traits is a testament to its success in this regard.

Interestingly, the generation algorithm and 1/1/x rarity distribution also resolve the tension between mass production and customization . In traditional manufacturing, manufacturing customized products at scale is often impractical and costly. However, generative algorithms can be integrated directly into manufacturing hardware such as 3D printers, CNC machines, laser printers, automated looms, and other equipment, providing feasibility in production and distribution while providing scarcity and uniqueness.

The interplay between social dynamics and rarity, digital creation and physical production, lays the foundation for new consumer goods and luxury goods that combine algorithmic randomness, end-user parameterization and verifiable uniqueness to Meet consumer needs.

The history of generative manufacturing

Artists have always used technology as a means to explore new dimensions of creativity. Over time, this relationship evolved significantly, moving from a purely artistic endeavor to a fusion of art and manufacturing.

- 1960s - Early Generative Art : Artists begin experimenting with algorithmic processes to create artwork. Using early computers and programming languages and tools such as pen plotters, artists such as Manfred Mohr, Vera Molnár and Harold Cohen Start creating algorithm-driven art.

- 1980s - Personal Computer and Software Revolution : The advent of personal computers makes digital tools easier to use. This allows more artists to try out these novel artistic processes.

- 1990s-2000s - The Birth and Expansion of Additive Manufacturing : As 3D printing emerged and developed, artists saw new opportunities. Generative artists are beginning to experiment with these tools, creating sculptures and installations directly from software-driven designs.

- 2000s-2010s - Digital Art Meets Digital Fabrication : As both fields mature, digital artists will collaborate with manufacturers, architects, and designers to realize large-scale installations. Projects such as The Living's Hy-Fi tower, which uses organic bricks grown from cornstalks and mushrooms, incorporate generative design principles into their conception and are created using modern manufacturing methods. Around this time, software tools tailored for artists, such as Processing, enabled them to create complex procedural art without requiring deep programming knowledge.

- 2010s - Maturity of tools and methods : Generative art platforms and frameworks (such as openFrameworks and TouchDesigner) grow in popularity. These tools are combined with easier-to-use and advanced 3D printing, laser cutting and CNC milling technologies to enable seamless production. For example, artists like Nervous System use generative algorithms to design unique jewelry and clothing that are then 3D printed.

- 2020s - Convergence and collaboration : The lines between art, design and manufacturing are becoming increasingly blurred. Art installations, architectural structures, and even everyday objects now demonstrate the unique aesthetics and functionality this combination can produce. Notably, on-chain art at this time has revived interest in the field of generative art, using encrypted inputs as random seeds for on-chain collections. Coupled with new primitives in the digital physical space, we are gaining a new beachhead at the marriage of digital creation and physical production.

Today’s generative artists don’t just create art; They are redefining consumer goods, integrating aesthetic value with functional design, and pushing the frontiers of art and industry.

Web3 Experiment

In web3, there are various early experiments with generative manufacturing.

Neolice loom by Trame

Neolice loom by Trame

Craft Nouveau by Trame x CPG is a series focused on combining traditional craftsmanship with generative art, demonstrating the ability of generative code to preserve the artistic styles of global cultures. Navette by Alexis André is the first collection from Craft Nouveau, in which Alexis wrote an algorithm that generates images designed to be woven automatically by the Neolice Loom - an automated loom that extracts codes to weave physical pieces.

The fx (hash) ecosystem has experimented a lot with manufacturing - likely due to its permissionless self-publishing approach. Klangteppich is an ever-evolving, dynamic NFT that provides instructions to the loom and allows collectors to receive any physical fragment that generates a frame. Mini Dahlias includes instructions in the NFT’s metadata to create a 3.5 x 2.0 miniature sculpture from 14 layers of laser-cut alpha-cellulose backing. Nuages may create variations on Joanie Lemercier's Cloud series, where the output is code recreated by a plotter in physical space.

Nuages may exist on fx(hash)

Nuages may exist on fx(hash)

Alongside crafts and art, fashion is one of the most explored avenues for derivative manufacturing. Iteration-002 produced by 9dcc is an early example of generative design combined with physical products. Iteration-002 shirts are produced in real time using a printer plugged into SnowFro's Squiggles algorithm. The printer relies on the algorithmic randomness of the source code to determine the characteristics of the design printed on the shirt, and follows the same distribution of characteristics as the original 10k series.

9dcc iteration-002

9dcc iteration-002

Tribute Brand also recently remixed the Chromie Squiggle algorithm to create apparel. Chromie Squiggle holders can generate personalized sweaters using their unique Chromie Squiggle, while others can generate one-of-a-kind sweaters via the original Chromie Squiggle algorithm. This drop includes digital and physical ODDS sweaters derived from the Chromie Squiggle source code. These digital objects serve as blueprints for future sweater versions and can be used as skins in immersive environments. Each unique ODDS digital object is redeemable for a corresponding ODDS physical sweater, handcrafted by the Waste Yarn Project.

Other notable generative fashion projects include mmERCH and RSTLSS , both of which plan to conduct experiments around algorithmic randomness and design.

Deep Objects takes a slightly different approach to generative products, using a community curation engine to pare down the one million designs generated by its GAN AI model into a single design. This final piece will now be 3D printed in a community-driven showcase of generative product creation.

Generative Manufacturing Stack

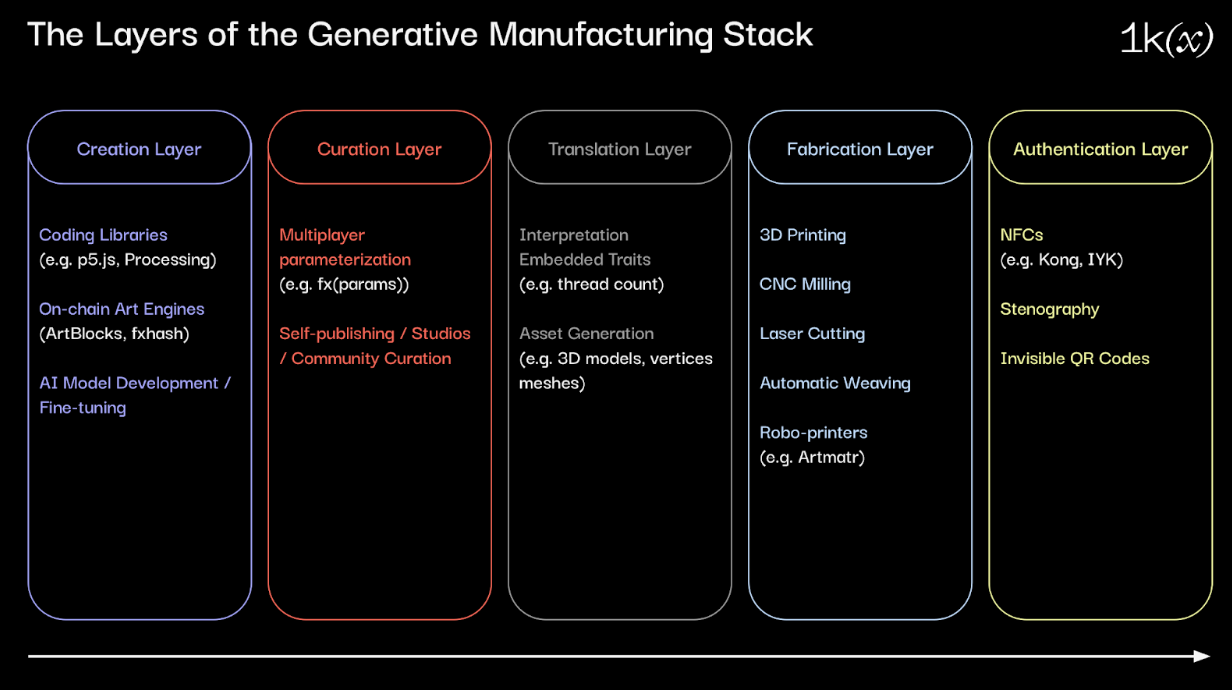

The generative manufacturing stack can be divided into 5 layers:

- Creation : The initial stage of generating a design or concept using an algorithmic or artificial intelligence process.

- Curation : The process of selecting and refining generated designs to achieve desired results or specifications.

- Translation : Converting a digital design into machine-readable instructions or code for use by manufacturing equipment.

- Fabrication : The physical production or manufacturing process of a design using a variety of materials and equipment.

- Authentication/Linking : Verify the authenticity of a manufactured product and link it to its digital twin to ensure provenance.

Create layer

Create layer

Creating products starts with code. Libraries like p5.js and Processing provide artists and designers with powerful tools for creating generative art. These libraries scale with on-chain randomness using seeds generated from tx hashes, token data, block headers, etc. On-chain art engines like ArtBlocks Engine and fx(hash) allow artists to easily insert these random seeds into their code and mint artwork directly on-chain.

For AI artists, this layer focuses on model development and fine-tuning to create the desired aesthetic. They typically start by choosing a pre-existing AI model, such as a generative adversarial network (GAN), as a base. Through backpropagation, the model weights are gradually increased to generate artwork that matches the desired style. The artist provides feedback by curating the most engaging output and merging it back into the training dataset. This iterative process continues, refining the model's performance and allowing the artist to explore different possibilities. In addition to custom models or stable diffusion LoRA, there are tools that simplify this process, such as Scenario.gg .

Management

After creating the layer, the output of the code can be further refined to match the user's preferences. In creative coding environments, this often takes the form of multi-player parameterization, like that provided by fx(params) for fx(hash) .

In the context of AI generative models, governance is typically accomplished through the broader community of token holders, as is the case with Botto ’s generative algorithm and Deep Objects ’ community design process.

Studio or self-publishing is the final step in the curatorial process. This is where generative studios like Trame and ArtBlocks come in to showcase their work to the public, or fx(hash) as a self-publisher.

translation layer

Once the algorithm and design are set, the resulting product must be converted into machine-readable instructions for manufacturing the hardware. Translation is a relatively simple process whose goal is to reproduce the original as accurately as possible in physical space.

Translation can be accomplished in several different ways, including:

- Artist/Collector Interpretation. The easiest way to translate an object is to leave the physical design specifications to the artist or collector. They will determine how a piece will be made, what materials will be used, exact dimensions, and more.

- Embedded features. A more scalable and interesting approach is to embed the physical information required for manufacturing into the NFT itself. Features in the NFT metadata define areas of interpretation (e.g. tapestry thread count, thread size, weaving instructions, etc.).

- Direct instantiation. A third approach is to generate interpretable assets directly: the generation algorithm is already adapted to manufacturing hardware, or the output of the algorithm is a 3D print file or the vertices of a 3D mesh.

manufacturing layer

After translation, the resulting goods are manufactured. The manufacturing phase is a critical step in converting virtual designs into physical objects. Various technologies such as 3D printing, CNC milling, laser cutting, robotic printers and automated weaving can be used to create objects of different materials and shapes.

Trame's Generated Pottery

Trame's Generated Pottery

For Trame's first collaboration with Alexis Andre, mentioned above, Neolice Loom was used as the fabrication hardware. Neolice Loom takes the artist's custom script and reinterprets the code into 3D space through weaving. Trame is also expanding into new mediums - the image above highlights experiments in generating pottery.

While Artmatr is specifically aimed at today's generative art production, it highlights what advanced fabrication tools can do for the physical production of digital products. Artists work with the Artmatr team to submit a variety of digital file formats such as code, 3D models, PSD files (Photoshop), vectors, and animations. Next, they define the physical "thread," including parameters such as medium (oil, UV, acrylic), substrate, size, and more. Ultimately, this is achieved through the use of machines such as robotic arms and six-axis printers. Using different techniques such as inkjet printing, airbrushing and extrusion, the resulting topology can be 2D, 2.5D or 3D.

Authentication/Linking Layer

Once a physical object is created, it needs to be linked back to its digital twin. This is similar to digital-physical processes in other spaces such as fashion. Near field communication chips, shorthand and QR codes manufactured using Kong and IYK are just some of the technologies that connect the digital with the physical and provide authentication of origin.

Check out our recent article on digital physical infrastructure, or our article on digital fashion , which dives into fashion-specific digital physical strategies.

future possibilities

Going forward, we expect existing on-chain generated art to serve as a program for derivatives. We've seen this through the use of Squiggles in various fashion projects, and another early example is Terraflows , a flow field study built on the Terraforms art program. This kind of network art allows for a fascinating reinterpretation of generative art in physical space. For example, Fidenza Art Script can be used to create architectural layouts for 3D printed houses.

Another interesting possibility for the future is the tokenization of decentralized manufacturing facilities for the mass production of generated goods in some kind of physical infrastructure network. Hobbyists and commercial makers with the appropriate equipment can print or create works by bidding on jobs posted by collectors or artists. Tokens can meter this hardware network and help guide the initial cost of the manufacturing facility. This works particularly well with the CC0 paradigm with on-chain code.

Taking this a step further, synthetic biology and/or chemical fabrication could also be an interesting avenue for generative quality: for example, generative codes could be used to algorithmically determine the characteristics of laboratory-grown crystals, the phenotype of plants, etc.

—

We firmly believe in a digital-physical future where online networks connect to physical spaces. Generative design, including algorithmic randomness, end-user parameterization, and verifiable uniqueness, is one such program that we expect to port—with existing manufacturing hardware enabling this.

If you are building at the intersection of art & technology + digital & physical, please contact us .