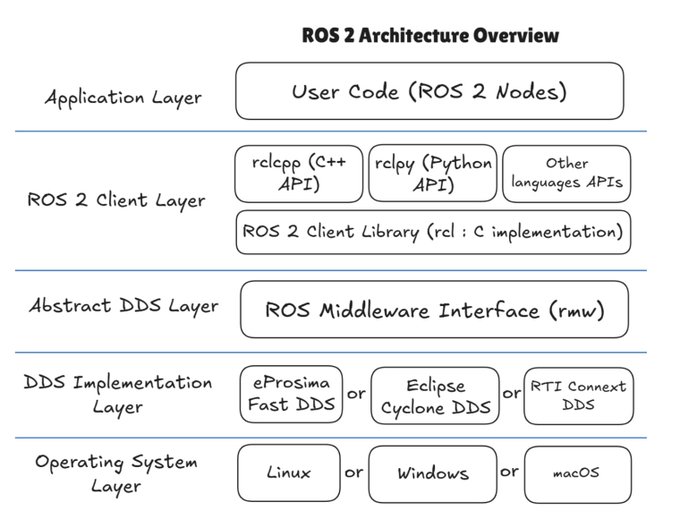

𝗥𝗢𝗦 𝟮 (𝗥𝗼𝗯𝗼𝘁 𝗢𝗽𝗲𝗿𝗮𝘁𝗶𝗻𝗴 𝗦𝘆𝘀𝘁𝗲𝗺 𝟮) 𝗢𝘃𝗲𝗿𝘃𝗶𝗲𝘄 ROS 2 is middleware for building robot software. It handles message-passing between processes, node discovery, and data serialization - the infrastructure layer so you don't write TCP sockets yourself. Key difference from ROS 1? ROS 1 used a custom TCP protocol. ROS 2 uses DDS (Data Distribution Service) - a standard that supports QoS policies, security, and deterministic communication timing. A factory arm needs guaranteed 1ms response times. ROS 1 couldn't promise that. ROS 2 can. How does it differ from alternatives? vs writing custom: you get pub/sub, service calls, parameter servers, lifecycle management out of box. Building this takes teams 6-12 months. vs proprietary frameworks (ABB RobotStudio, KUKA KRL): ROS 2 is hardware-agnostic. The same code runs on different robot brands. And you may know these big guys that already use ROS 2: ➤ Bosch: warehouse robots (2,000+ units deployed); ➤ NASA: VIPER lunar rover; ➤ Tier IV: Autoware autonomous driving stack (production vehicles in Japan); ➤ Amazon: some Proteus warehouse robots; ➤ BMW, Toyota: R&D and production line automation. Adoption increased 3x from ROS 1 to ROS 2 in industrial settings (2019-2024), per Open Robotics' survey of 3,500 developers.

From Twitter

Disclaimer: The content above is only the author's opinion which does not represent any position of Followin, and is not intended as, and shall not be understood or construed as, investment advice from Followin.

Like

Add to Favorites

Comments

Share

Relevant content